High Pressure Laminate Sheet (HPL Sheet) is a popular choice for interior design due to its versatility and durability. From countertops and cabinets to flooring and wall panels, HPL is a design choice that offers both style and functionality. In this blog, Discover the benefits of HPL sheets and how they enhance any interior space. Find valuable insights and info about HPL design in our blog, to inspire your next furniture or interior project.

What is High Pressure Laminate (HPL)?

High Pressure Laminate Sheet (HPL Sheet) is a type of decorative laminate used for furniture, countertops, and interior design. HPL Sheet is a durable and hard-wearing material that is resistant to scratches, impact, and moisture.

HPL at Advance Laminates is available in a wide range of hpl sheet colors, patterns, and hpl sheet textures, and can be customized to suit different design needs. It is often used in commercial and institutional settings where durability and hygiene are important, such as hospitals, schools, and offices, but is also commonly used in residential settings.

What is High Pressure Laminate made of?

- HPL Sheet (HPL Laminate Sheet) is a type of decorative laminate that is made by layering multiple sheets of kraft paper with a decorative layer and a protective overlay. These layers are then fused together using high heat and pressure, resulting in a durable and hard-wearing material.

- HPL’s kraft paper is made from processed, bleached wood pulp to remove impurities. The paper is coated with melamine resin to enhance durability and moisture-resistance of the laminate.

- The decorative layer of HPL can be made from a variety of materials, including paper, fabric, or wood veneer. This layer is printed with a pattern or design using high-quality inks or dyes, and is then bonded to the kraft paper layer.

- Finally, a protective overlay is added to the laminate to help protect it from scratches, impact, and moisture. The overlay is made of melamine or phenolic resin, applied to the decorative layer with heat and pressure.

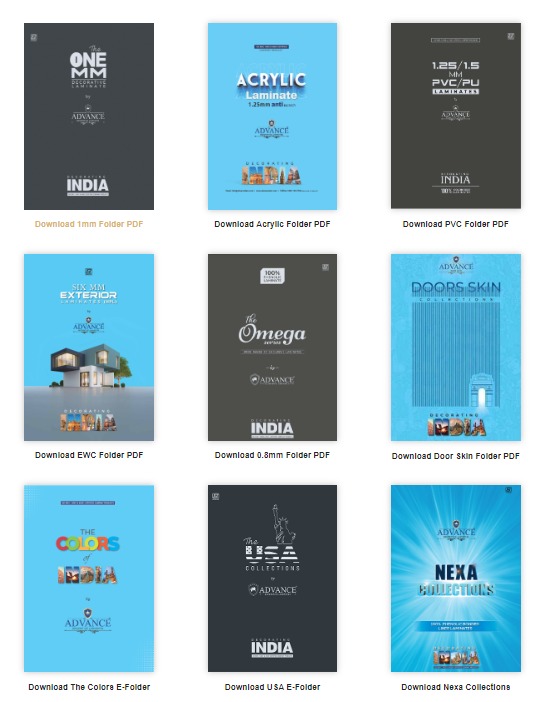

Download our laminate Catalogue

High Pressure Laminate (HPL) Specifications

HPL is a versatile and durable material for furniture and interior design, with a wide range of applications. Here are some specifications of Advance Laminates that are commonly associated with HPL:

- Thickness: HPL is available in a range of thicknesses, typically ranging from 0.5mm to 1.5mm. Thicker laminates may be more durable and impact-resistant, but they may also be heavier and more difficult to work with.

- Size: HPL is available in a range of sizes, typically ranging from 4×8 feet to 5×12 feet. Larger sizes may be more cost-effective for larger projects. However, they may also require more space and specialized equipment for cutting and installation.

- Colors and Patterns: HPL sheet design is available in a wide range of colors and patterns, including solids, wood grains, and abstract designs. Many manufacturers offer custom designs and color matching to suit specific design needs.

- Finish: HPL is available in a range of finishes, including matte, gloss, and textured. The finish can affect the appearance and feel of the laminate, as well as its durability and resistance to wear and tear.

- Performance: HPL is a highly durable material that is resistant to scratches, impact, and moisture. It is also resistant to heat and chemicals, making it ideal for use in high-traffic areas or areas where spills and stains are common.

- Certifications: Many HPL manufacturers offer laminates that are certified to meet specific industry standards, such as those for fire resistance, antibacterial properties, or environmental sustainability.

Benefits of High Pressure Laminate:

High Pressure Laminate (HPL) is a versatile and durable material that offers many benefits in furniture and interior design. Here are some of the key benefits of HPL:

- Durability: HPL sheet is highly durable and resistant to scratches, impact, and moisture, making it ideal for use in high-traffic areas or areas where spills and stains are common.

- Versatility: You can find HPL sheet in various colors, patterns, and textures, making it a versatile material to achieve different design styles.

- Ease of maintenance: HPL sheet is relatively easy to clean and maintain, making it a popular choice for areas where hygiene is important, such as hospitals and schools.

- Cost-effective: HPL sheet is generally more cost-effective than other materials such as natural wood or stone, making it an affordable option for a wide range of projects.

- Customizable: HPL sheet can be customized to suit specific design needs, with many manufacturers offering custom designs and color matching.

- Environmentally friendly: HPL is often made using recycled materials and is recyclable itself. Making it an environmentally friendly option.

- Fire-resistant: Many HPL laminates are certified to meet specific fire safety standards. Making them a safe option for use in public and commercial spaces.

High Pressure Laminate Sheet Pros and Cons:

High Pressure Laminate (HPL) is a versatile and durable material that offers many benefits for interior design and furniture projects. However, like any material, it has its own set of pros and cons. Here are some of the pros and cons of HPL:

Pros:

- Durability: HPL is highly durable and resistant to scratches, impact, and moisture, making it a long-lasting material for high-traffic areas or areas where spills and stains are common.

- Versatility: You can find HPL sheet in various colors, patterns, and textures, making it a versatile material to achieve different design styles.

- Cost-effective: HPL is generally more cost-effective than other materials such as natural wood or stone, making it an affordable option for a wide range of projects.

- Customizable: Manufacturers can customize HPL to meet specific design requirements, including custom designs and color matching.

- Environmentally friendly: Manufacturers often make HPL using recycled materials, and it is also recyclable, making it an environmentally friendly choice.

- Fire-resistant: Many HPL laminates are certified to meet specific fire safety standards, making them a safe option for use in public and commercial spaces.

Cons:

- Installation: HPL can be difficult to install, especially for large-scale projects or for areas with intricate designs.

- Limited repair options: Repairing HPL can be challenging as sanding or refinishing is not an option due to the solid sheet nature of the laminate.

- Limited design options: While HPL is available in a wide range of colors and patterns, it may not offer the same level of natural variation and texture as natural materials such as wood or stone.

- Temperature sensitivity: HPL can expand and contract with changes in temperature, which can affect the appearance and durability of the material over time.

- Susceptible to fading: HPL laminates may be susceptible to fading or discoloration over time, especially if exposed to sunlight or other sources of UV radiation.

High Pressure Laminate (HPL) Design:

There are many different designs available for HPL, including solid colors, woodgrains, stone patterns, abstract designs, and more. You can print the decorative layer using various techniques, such as gravure printing, screen printing, and digital printing. Some HPL manufacturers offer custom designs as well. Here are some popular HPL sheet design categories:

- Woodgrains: HPL can replicate the look of real wood, including the grain patterns and texture. There are many different wood species and colors available.

- Stone patterns: HPL can also replicate the look of stone, such as marble, granite, and slate. These designs can range from subtle and understated to bold and dramatic.

- Abstract designs: HPL can feature abstract designs, such as geometric patterns, stripes, and swirls. These designs can add visual interest to a space.

- Solid colors: HPL can come in a wide range of solid colors, from neutral tones to bold hues. This versatility makes it easy to coordinate with other elements in a space.

- Custom designs: Some HPL manufacturers offer custom design services, allowing designers and architects to create unique patterns and color combinations.

Conclusion:

In conclusion, HPL sheet is a durable and versatile material with countless design options for furniture and interior projects. HPL’s key benefit is its versatility, with options for color, pattern, texture, and customization. Designers can achieve a unique look by integrating HPL with other materials, to match a specific aesthetic or design style.

India’s leading HPL manufacturer: Advance Laminates

Advance Laminate is a renowned manufacturer of high-pressure laminate (HPL) and sunmica design in India, acclaimed for its long-lasting style, trendy designs, and impressive performance. There are several uses for our paper-based composite material. This is the product for anyone looking to use it in both domestic and public settings. In terms of installation and maintenance, Advance Laminate High-Pressure Laminate panels are simple and multifunctional.

Advance Laminates may complement your creative idea effectively since the decorative layer is a printed sheet. Choose from mirror sheen, matte, scratch-resistant laminates, antibacterial protection & more for a unique look with HPL finishes. HPL laminate grades include antimicrobial, antifungal, antiviral, lab-grade, and abrasion-resistant options for diverse applications.

If you have questions about our range of High Pressure Laminate or to discuss your requirements, simply call 9821698171, or write to us at [email protected]