The versatility of mica sheets or laminates exceeds traditional limitations and finds applications across various sectors and industries. It has become an essential component for a variety of industries, including electronics, automotive, cosmetics, and construction. Mica sheet have been used for electrical insulation and are valued for their exceptional qualities. This unique natural material provides unmatched benefits for managing high temperatures, voltages, and amperages. Additionally, mica sheets offer durability and require low maintenance. Advance Laminates is a renowned manufacturer of laminates in India that offers durable laminate sheets for industrial uses. In this blog, you will learn about the versatility of mica sheets.

Introduction

Mica sheets are most commonly used in electrical insulation, but they are now finding more and more applications across a wide range of industries. These sheets offer exceptional insulating qualities for electrical components. Engineers and innovators are taking an interest in mica sheets because of their exceptional heat resistance, durability, and visual appeal. Furthermore, the mica sheet price is lower than that of other materials. Mica sheets are leading the way for innovation and improvement across a wide range of sectors, from enhancing the shine of cosmetics to strengthening concrete in building projects.

Unique properties of mica sheets

Mica sheets offer unique properties that set them apart from other materials. Their extraordinary heat resistance property enables them to endure high temperatures without experiencing major structural changes. Because of this characteristic, mica sheets are perfect for use in high-temperature applications such as thermal insulation coatings. Mica sheets have superior electrical insulating qualities, which makes them essential for producing electrical devices and components. They are the material of choice for insulating transformers, capacitors, and circuit boards because of their resistance to high voltages and ability to prevent electrical leakage. Mica sheets are highly valued not only for their electrical and thermal characteristics but also for their versatility and longevity. Mica sheets are extremely robust despite their thinness and lightweight. They can withstand mechanical stress and environmental impact without losing their integrity. Mica sheet color has a naturally sparkling aspect that elevates the visual appeal of several products in the interior design, automotive, and cosmetics industries. Overall, the unique properties of mica sheets like heat resistance, electrical insulation, durability, flexibility, and aesthetic appeal—make mica sheets a versatile option with a broad range of applications in various industries.

Unconventional Applications of Mica Sheets

Some of the unconventional applications of mica sheets are as follows:

1. Heat Insulation and Thermal Management

Mica sheets are becoming popular among engineers and innovators for unconventional applications, especially in the fields of thermal management and heat insulation. Mica sheet texture have proved quite helpful in dealing with thermal challenges across various industries. They are used in the automotive industry as thermal barriers to shield delicate components from heat generated by exhaust systems and engines. They are also used in aerospace technology, like in thermal protection systems, to protect satellites and spacecraft from extremely high temperatures that occur during atmospheric re-entry. Mica sheets are also used in industrial kilns and furnaces to maximize thermal efficiency and limit heat loss, which lowers energy usage and operational expenses.

2. Fire safety and flame retardancy

Mica sheets have become a versatile solution with unconventional uses across numerous sectors in the pursuit of improved flame retardancy and fire safety. These sheets are used in the construction industry and effectively reduce fire risk and raise safety standards, Construction companies can reduce the risk of property damage and fire-related incidents by improving the fire resistance of their buildings by using mica in insulation boards, wall coatings, and fireproof coatings. Additionally, mica acrylic sheet is used to make fire blankets and firefighters’ protective clothing, which adds another line of defense against heat exposure and flames. The unique qualities of heat resistance, durability, and flame retardance make sheets essential for improving fire safety measures in various industries.

3. Decorative Surfaces and Architectural Finishes

Wardrobe mica design are becoming increasingly popular in the fields of decorative surfaces and architectural finishes. They are widely known for their unconventional use in electrical insulation. Designers and architects who are looking for cutting-edge materials for interior design are taking an interest in mica sheets because of their aesthetic appeal and practical qualities. The unique use of mica sheets in decorative wall panels and surface coatings lends a touch of sophistication and elegance to homes, hotels, and business settings. With mica sheet for wardrobe, designers create eye-catching visual effects that captivate the senses and boost the ambiance of any space. Mica sheet is also used in architectural finishes, including decorative facades and textured coatings, where their resilience to weather and endurance guarantee long-lasting beauty and structural integrity. These sheets provide countless opportunities for producing aesthetically pleasing and functionally superior architectural works of art to enhance domestic interiors.

4. Insulating and Protective Packaging

Mica sheets are commonly used for electrical insulation, but they also have unique properties that make them ideal for protecting and insulating delicate products during storage and transportation. Mica sheets can be used to make insulating packaging materials for devices and electrical components. Sensitive electronics are kept safe from moisture, temperature changes, static electricity, and other external variables while still functioning because of the thin layers of mica sheets placed between packing layers. Furthermore, mica glass sheet are used to package products like food, cosmetics, and pharmaceuticals safely. Because of their strength and resistance to heat, they are ideal for lining containers as they provide an additional layer of insulation and a shield against the weather.

5. Artistic and Craftsmanship Applications

Mica sheets are becoming increasingly popular in the field of artistic expression and craftsmanship for their capacity to promote creativity and raise creative activities to new heights. These 3d mica sheet provide more than just a surface for industrial purposes; they are a unique medium on which artists, craftspeople, and artisans can experiment with new methods and produce beautiful artwork. Mica sheets have an interesting use in mixed-media art, where they are a flexible medium for sculpture, painting, and collage. Their inherent shimmering qualities give artworks more depth and dimension, producing captivating visual effects that capture the interest of viewers.

Sustainable Solutions with Mica Sheets

Mica sheets are becoming an important component in promoting environmentally friendly solutions across a range of businesses at a time when sustainability is of the utmost importance. Mica sheets have several qualities that support sustainable practices and efforts beyond their traditional uses. Their natural abundance and minimal influence on the environment during extraction and processing are important factors. As mica is a mineral that occurs naturally and is common in many places, it may be used for a variety of purposes and is a renewable resource. Additionally, mica sheets ensure lifespan and minimize the need for frequent replacements due to their extreme durability and resistance to degradation. For the product’s existence, this endurance results in less waste being generated and a smaller environmental impact. Also, the insulating qualities of mica lower energy usage and greenhouse gas emissions in industries like electronics and buildings.

Conclusion

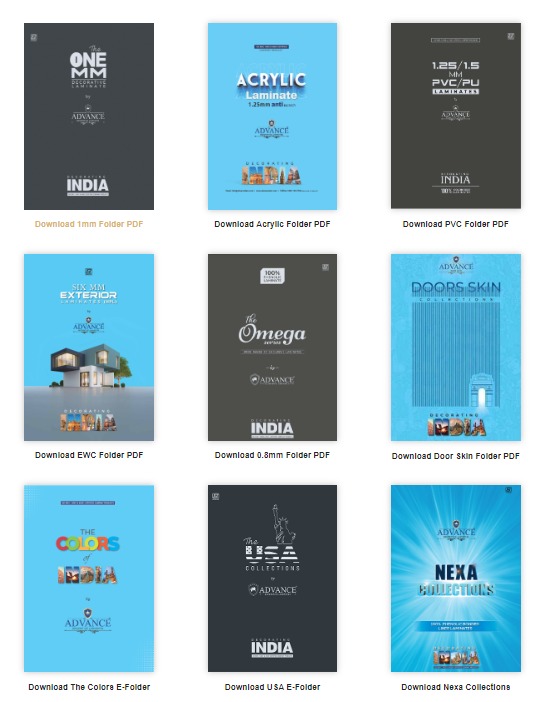

Beyond their traditional use in electrical insulation, mica sheets’ versatility shows a wide range of creative applications in a variety of industries. Mica sheets are a technologically innovative solution for a wide range of challenges, from construction to cosmetics, automotive to electronics. These sheets have extended their possibilities in a variety of areas due to their special combination of qualities, which include heat resistance, electrical insulation, durability, and aesthetic appeal. Advance Laminates is a known laminate manufacturer that offers mica sheet for kitchen as well as electrical insulation.

FAQs

1. Can mica sheets be customized for specific applications or requirements?

Yes, mica sheets can be customized for certain uses or requirements. For use as decorative materials, electrical insulation, or thermal management, these sheets can be made to order in terms of size, thickness, and color. You may get exceptional performance in a variety of industries, including electronics, automotive, and aerospace, by customizing mica sheets. Furthermore, businesses may guarantee that the mica sheets they receive are just right for the use for which they are designed. As a result, their activities will become more efficient and productive.

2. How do mica sheets compare to other insulation materials in terms of performance and cost?

Mica sheets offer exceptional performance and cost-effectiveness when compared to other insulation materials. It is perfect for applications that require durability because of its strong dielectric strength, temperature resilience, and low thermal conductivity. The initial cost of mica is slightly higher than that of other options, but its longevity and durability frequently lead to reduced overall expenses. It is also an attractive option in terms of both performance and cost-efficiency because of its customization possibilities, which add value and guarantee the best performance for various sectors.

3. Can mica sheets be recycled?

Mica sheets eliminate waste and lessen the impact on the environment because they are recyclable and have eco-friendly qualities. At the end of their lifespan, mica sheets help conserve resources and encourage ecologically friendly behaviors. This contributes to a more sustainable approach to mica utilization in various industries.

4. Are mica sheets environmentally friendly?

Mica sheets are a sustainable option for various applications because of their eco-friendly qualities. Mica is a mineral that occurs naturally and can be found in deposits all over the world. The technique of extracting it usually has little effect on the environment. Furthermore, mica is safe for the environment and human health because it is non-toxic and chemically free. Furthermore, compared to certain synthetic materials, mica requires less frequent replacement, which lowers waste formation due to its lifespan and resilience. To optimize the environmental advantages of mica sheets, manufacturers follow ethical sourcing guidelines.