Welcome to this video by Advance Decorative Laminate!

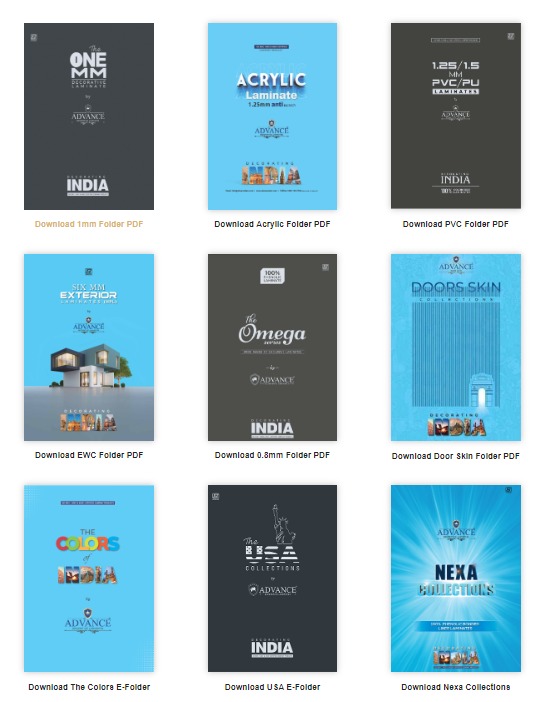

Advance Decorative Laminate manufactures the most innovative and unique decorative laminates, and provides outstanding customer services. Laminates are used brilliantly in modern construction to enhance the beauty of the space. Extremely attractive and available in different varieties, laminate is the top choice of one and all.

Sometimes, cracks can ruin the appearance of laminates when they are not glued skillfully with caution.

Let’s know about what causes cracks in laminate while installation?

Substrates and laminates are not made of plastic. Changes in weather and moisture conditions cause them to expand and contract, leading to cracks in the laminate. The moisture content of most of the substrates such as particle board, MDF and plywood is higher than the moisture content of laminates. This is why substrate contracts more with increase in temperature. This contraction due to increase in heat exerts pressure on the laminate and the substrate and crack can be noticed at the place where they are least bonded.

Therefore, always use only SH grade adhesive to ensure greater bonding between laminate and substrate.

What to consider to avoid cracks in laminates?

Carefully avoid reasons of cracks in laminates.

Reason number 1:

Insufficient gap between the laminates to expand

When two laminates are glued without a gap, expansion can cause stress and crack at the point of contact. Therefore, always remember to leave a gap of at least 2mm while gluing two laminates so that pressure doesn’t arise. This gap prevents crack and overlap while joining two laminates together.

Reason number 2:

Variation in the moisture content of laminate, substrate and worksite

If the moisture content of laminate or substrate is not similar to the humidity conditions at the worksite, then laminate is highly prone to cracks. In order to bring their moisture content at the same level, put laminate and substrate at the worksite 48 hours prior to begin working. Along with this, keep laminates pressed between two ply boards sot that they can be flattened completely.

Reason number 3:

Uneven or unsmooth corners

Make sure that there remains no fine cracks or hair-line cracks at the corner. When a laminate is cut using a saw, it makes feeble corners which crack easily. Rub the corners using sand paper or regmark after making a cut-out to smooth the uneven edges. Make sure the saw is sharp enough to cut the laminate.

Reason number 4:

When there is a cut angle of 90o on laminates, it creates a pressure and causes crack in the laminate.

If the corners are cut at an angle of 90o, it’s uncertain for two edges to meet at one point. One of the two edges might get an elongated cut. Such corners are highly prone to cracks. In order to avoid this, drill a 3 mm diameter hole at the four corners of the cut-out area. Make sure there are no extra cuts at the corners. Rub them with sand paper after drilling and cutting.

Reason number 5:

Crack in laminate due to hammering an iron nail

Nails have to be hammered into the laminated wall if you want to hung paintings or pictures. But, the point where nails are hammered into the wall experience immense pressure, leading to cracks. Instead of hammering, choose drilling to avoid cracks.

For drilling, use round drills only.

For your help, all these precautions are mentioned on the Advance Decorative Laminate Company packing paper sheet. Read all these points carefully and apply the laminates accordingly. If all these precautions are followed while laminate installation, these problems can be avoided.

Use of laminates can enhance the overall appearance of any establishment be it a school, a college, an office or a house, and creates hyper-realistic complex designs.

Advance Decorative Laminate is always at your service. Call on our toll free number 1800 103 4740 for any assistance.

Our staff is always available to help you from here .