What is Laminates?

Composite laminates are a plate with many layers upon layers of fibre reinforcement and hardened resin. Adjustments and modifications can be implemented to the number of layers, the type of fibre (carbon, glass, or something else), the arrangement of the fabric (e.g., woven, stitched mat, uni-directional), the type of resin, and other things to make a structural element that meets a certain requirement. Raw materials (fibre, resin, and usually some filler) can’t be used as building materials on their own, but when they’re put together, the product gains qualities that make it perfect for a construction site. Laminates, which are sheets of hardened composite material, are often cut into small pieces for mechanical testing to make sure they have the character traits that were pledged.

What are the prerequisites for choosing a laminate?

You are not the only one who feels like there are too many options for decorating spaces with laminate materials. Many customers choose laminate finishes that are of high quality, i.e., high-pressure laminates that look great in modern settings.

- Meticulously choose the colours and patterns of the laminate

Remember that the colour combinations you choose will have a big effect on how your space looks as a whole, so take your time and pick the best ones. The beautiful shade of red you generally see in big office spaces might make your house look even smaller. Choose a colour based on how big the room is, how much natural light comes in, how you cook, and, of course, what you like.

- Opt materials are made of high-pressure laminates.

High-pressure laminates are stuck to the substrate with a lot of heat and pressure. Compared to low-pressure laminates, they last a lot longer. This is especially important in the kitchen, where all surfaces must be heat- and moisture-resistant. The thickness of these laminates ranges from 0.70 mm to 1.22 mm. Even if you use a high-pressure laminate, you shouldn’t let water and moisture stay on it for a long time.

- Trim for the Laminate Edge

Your modular kitchen cabinets, bathroom and drawers in rooms and office spaces will usually have an edge-banded finish, no matter what kind of laminate you choose. Edge bands are thin laminate strips that are used to finish the edges of your shutters. They give your bifold doors a clean look and make them more stable in size. The curve band seals the bifold doors’ edges, keeping moisture from getting into the parts within them.

- Anti-Bacterial and Flame-Resistant Laminates

Check to see if the things you want to buy are resistant to fire and have antimicrobial activity properties to make sure they will last and stay clean. Surfaces that are flame resistant don’t catch fire easily. They can also stand up to heat and smoke better. Germs and bacteria won’t grow on surfaces that don’t allow them to, which is a huge benefit for any family.

Laminate is broadly categorised into High-Pressure Laminate and Low-Pressure Laminate:

High-Pressure Laminate (HPL)

Several methods were used to make HPL, which stands for high-pressure laminates. HPL is made of six layers of resin-soaked kraft paper, decorative sheets, and a protective layer which is visible. The layer is then put under a lot of pressure and heated to more than 140 °C. To make a high-pressure laminate, these are put together under high pressure and heat. High-pressure laminates don’t get scratched or burn, are easy to clean, and are safe to use. When choosing furniture for a lab, office, commercial kitchen, or healthcare facility, HPL should be taken into account.

Low-Pressure Laminate (LPL)

Low-pressure laminate (LPL) is very different from high-pressure laminate (HPL) in many ways. LPL, also called direct-pressure laminate or melamine board, is made of one or two layers of decorative kraft paper that are pressed at much lower pressures and temperatures (29–435 psi at 335–375 °F) onto a substrate like particleboard.

LPL is the least expensive laminate option because it requires less time and fewer components to make. LPL is made for low-impact uses, like vertical surfaces, and is not as strong or resilient as HPL.

Other Types of Laminates

- Regularly sized and compressed laminate sheets

The thickness of these two types of laminates is not the same. Normal laminate, which sticks to wood or plywood, can be anywhere from 1.3 mm to 8-9 mm thick. Compressed laminates that can stand on their own can be used instead of wood or plywood.

- Decorative and Industrial Laminate

Decorative laminates are known for their good looks and a wide range of patterns, textures, colours, and finishes. The thickness of this material is about 1 mm. They are used to make furniture like cabinets, shelves, doors, and office cubicles because of how they look and how well they protect them.

Industrial laminates are used in industrial settings because they can handle heavy loads and don’t wear down easily. They are used to make storage containers, circuit boards, and other types of industrial furniture. There are also fire-resistant kinds that are used in kitchen laminate, hospitals, colleges, and airports. Antibacterial and antifungal laminates are used in hospitals and daycare centres, and outdoor UV laminates are used for billboards and cladding.

- Laminate based on colour, finishes and pattern

Lamination materials can be made to look and feel different, so they can go with any style of interior design. It comes in a number of colours and beautiful themes or patterns. It is also divided into larger groups based on design and surface finish, such as laminate type.

- Matte finish Laminate– Because these laminates aren’t shiny and don’t have a lot of shimmers, they look “matt.” The best thing about these laminates is that their dull look makes defects and scratches less obvious. They can be used on floors, kitchen cabinets and countertops, and in business settings.

- Shiny and glossy textured laminate– Unlike laminates with a “matt” finish, the surface of these laminates looks “glossy” or “shiny.” This shiny finish gives the home furnishings or room a rich look and often makes them stand out and feel enticing. People often see these laminates in restaurants, spas, hotels, and the event business. Because they are easy to maintain, they are often used for kitchen cabinets.

- Metallic finish laminates– The surfaces of the furniture look like metal because of this composite material. They are strong and easy to clean and take care of. Metallic laminates are used in business buildings like offices and showrooms.

- Textured surface laminate– Textured laminates can be felt on the substratum. They are a type of decorative laminate that adds to the beauty of the area by making amazing things happen. Most of the time, these laminates are used to cover walls, make floors, and build commercial buildings.

- Single-coloured laminates- Mono-glossic Laminate– These are the most common laminates. The whole laminate sheets is one solid colour, with no patterns or textures. They are great for upper cabinets in the kitchen and bathroom.

- Leather sheet laminate– When these laminates are put on a surface, they make it look like leather. They look good on cabinets and other pieces of furniture, such as the back of beds and shelves.

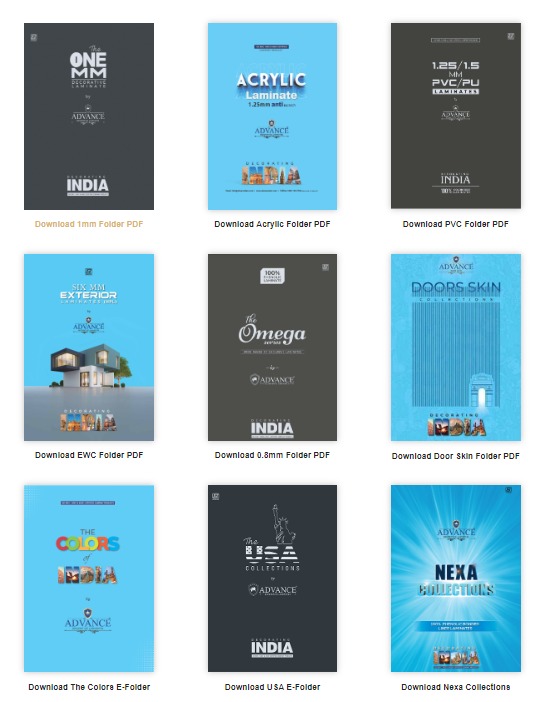

You can rely on us, Advance Laminate

Advance Laminates is one of the best laminate companies in India. It has a long history of excellent craftsmanship, unbeatable quality, and a relentless commitment to excellence. With a production capacity of 100,000 laminate sheets per year, we’ve always made sure you could get high-quality products. From the start, new technologies and creative solutions have led the way. We can help architects, interior designers, and end-users add elegance and personality to their ideas for home decor.