When it comes to construction materials, HPL (high-pressure laminate) has been around for a long time and has seen extensive usage both inside and outside the house. HPL panels have been tested in the laboratory and on buildings in different regions of the globe, and the findings have shown that they are highly durable. Alluringly, the wide range of product options provides architects with a great deal of freedom to express themselves via distinctive facades that get accolades. The combination of HPL panels with a waterproofing membrane attachment technology may help in the creation of environmentally friendly and high-performance buildings. Installation on-site is simple, requiring just the use of standard tools and attaching materials. All of these things can be found in buildings that are used for education, multifamily housing, mixed-use, public transit hubs, medical services, and retail.

When it comes to HPL wall cladding panels, architects have access to a wide range of materials from which they had to choose. The following is a list of the most frequent design decisions.

Multiple surfaces finishes: HPL laminates have many standard finishes. Other common facade alternatives include uniform, solid hues. Some treatments mimic the beauty and sleekness of raw or polished facade metals with less weight and cost. Similarly, wood grain or stone panels give a natural aesthetic with stained texture possibilities. Metallic coatings reflect light, are predictable, yet provide an interesting, creative, and distinctive aesthetic.

Numerous ranges in colours: Since there are so many common colours, it’s affordable to utilise numerous colours on a facade to produce complex designs. For major projects, it’s viable and reasonable to engage with a manufacturer to generate custom colours for expressive facades.

Multipurpose in nature: General opaque wall portions are the core of facade design, but HPL panels may also be employed in auxiliary or aesthetically supportive places. Soffits, canopies, sunscreens, and balcony enclosure panels are examples. although it’s not appropriate for floors or roofs.

Customized Design: Not all facades need substantial cladding. Perforations may be wanted for design, ventilation, or other reasons. In this situation, perforated HPL panels might follow a conventional pattern or a bespoke design. The perforation size might vary greatly.

HPL Panel Performance Parameters:

It is always preferable to discover and employ a cladding product that looks excellent and offers a great deal of design flexibility, but it must also operate as envisioned. In this way, HPL panels provide a multitude of advantageous characteristics.

Extreme climate acceptance: HPL wall cladding panels are suited for use in places with especially hard circumstances, such as saline sprays, high temperatures, and severe weather occurrences. Panels are constructed to endure exposure to the weather.

Colour Stability: Expedited and real-time testing of HPL panels and samples shows organoleptic properties. Many panels show slight fading or other alterations. Manufacturers like putting new product parts next to an old façade and trying to spot the difference. This benefits the original façade and makes extensions or renovations simpler since the new panels won’t be visibly distinguishable from the existing ones.

Panel integrity: The laminated HPL and resins utilized add to the panels’ strength and stiffness. Density and integrity are excellent even at thinner thicknesses. In addition to its own weight, it can withstand severe winds and other loads. Contextual factors may require additional thickness and strength. Cutting the panel doesn’t damage its strength or integrity. Shaping the cut edges, like shaping cut hardwood, protects the product’s integrity without concern of moisture seepage. Phenolic resins resist this.

Low in Maintenance: These performance properties make HPL panels easier to clean. The thick, resistant surface makes dirt, filth, and graffiti easy to remove. This low-maintenance feature often lasts the building’s lifetime At least one producer employs electron beam curing to ensure the layer’s durability. The outermost layer may be developed as an environmental barrier coating for external cladding protection.

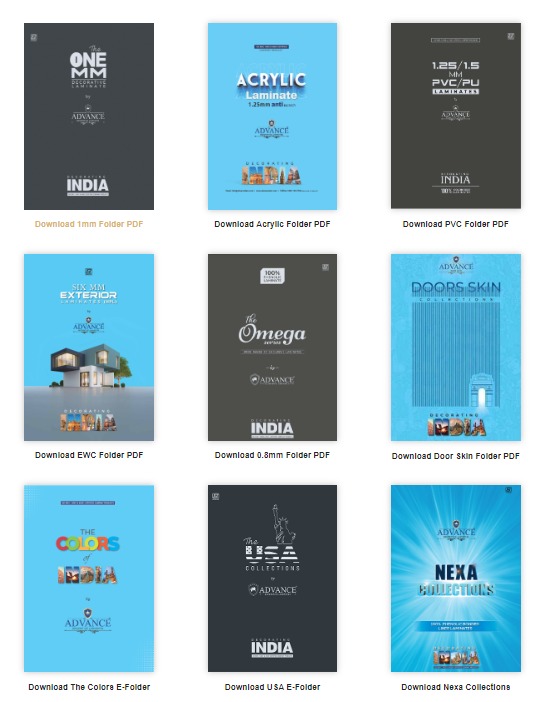

Why should you use Advance Laminates as the outside wall cladding?

There may be various producers of high-pressure laminate on the market. However, Advance Laminates has the finest wall cladding panels available. Listed below are a few advantages that make these panels superior to all others:

- Advance Laminates’ high-pressure laminate exterior cladding, which is created in India and inspired by Japanese technology, guarantees that there are no quality difficulties, such as colour fading of the laminates when exposed to extreme weather conditions.

- Astonishingly, Advance Laminates offers a ten-year guarantee term.

- Double-Hardening Resin: To provide unrivalled strength, Advance Laminates’ wall cladding panels are manufactured using a resin that is double-hardened via a laborious procedure.

- Perforation-Friendly: Everyone desires an aesthetically pleasing exterior. Certain individuals choose perforated facades for this purpose. Numerous producers of HPL laminate do not provide outside wall cladding that is perforation-friendly. However, Advance Laminates promises to address all of your concerns.

- Advance Laminates cladding uses extra-pressed virgin paper as opposed to recycled paper for the simple reason that recycling causes the paper to become brittle, reducing its strength and durability.